T-Formex Canoes

Royalex is back.

Back in the late ’90’s and early 2000’s I worked for Rutabaga, a big canoe and kayak store in Madison, Wisconsin. It was an exciting time to be a part of the paddlesports industry. Sea kayaking had exploded onto the outdoor industry scene and was rapidly becoming mainstream. Whitewater kayak designs were evolving so fast it seemed like there was a new design launched every week. Recreational kayaks were flying off the racks. Canoe sales were booming.

Back then, the most popular canoes we sold were made from a material called Royalex.

Royalex was a foam-core ABS plastic material with a vinyl outer skin. It could be molded into efficient canoe shapes and had a well-earned reputation for durability.

Fiberglass and Kevlar canoes were stiffer, lighter and more efficient, but when it came to toughness, nothing compared to Royalex. That toughness made Royalex THE choice for whitewater canoes, but also made it a favorite among recreational paddlers. Especially families looking for an affordable, low maintenance canoe.

In fact, Royalex canoes were so popular the staff often had trouble selling anything else. We sold ultralight Kevlar canoes for Boundary Waters trips and a handful of heavier Kevlar and fiberglass models for everyday paddling, but Royalex outsold these designs by three to one.

Why?

Value.

Why Royalex?

Royalex had a unique set of characteristics that set it apart from any other canoe material.

Royalex was tough. You could bang a Royalex canoe down a shallow rocky river and come away with nothing worse than a few scratches and a dent or two. There were loads of stories of people who had wrapped their canoes around rocks in whitewater and later stomped them back into shape and paddled home. Compared to even the strongest composite canoes Royalex was far more durable and impact resistant. It wasn’t even close.

The proof of this is how completely Royalex dominated whitewater canoe design. Early whitewater kayaks and canoes were made of composites. Then came plastic. Today, fiberglass and Kevlar whitewater kayaks have been almost entirely replaced by designs molded from highly impact-resistant polyethylene. In canoes, Royalex was the choice. It had all the impact resistance of rotomolded plastic but was lighter and stiffer.

The lighter weight of Royalex helped it gain traction as a good material for recreational canoes. Back then a typical plastic canoe cost about $700 and weighed close to 90 pounds. A similar design in Royalex might cost $500 more, but it weighed twenty pounds less. Seventy pounds was light enough for a young couple to get on top the car. 85 or 90 pounds wasn’t.

And then there was the scratching thing.

When you scratched a Royalex boat, the scratch was the same color as the hull (at least until you wore through the outer skin). The gel coat on the outside of composite canoes scratched white. This meant that even a well used Royalex canoe tended to look better than a composite canoe after a few years. It’s a small thing, but it was surprising how often it came up when we talked to people about canoes back then.

The scratching thing was part of what you might call the “worry free” aspect of Royalex. If you bought a Royalex canoe odds were that you would never have to do anything in the way of upkeep beyond replacing a seat from time to time. If you really beat the hell out of in in whitewater you might need to put some skid plates on the ends. That’s it. No gel coat repair. No fiberglass patching. Virtually maintenance free.

These factors added together to give Royalex a unique position in the canoe market. Royalex canoes were affordable, tough and worry free.

They were a great value.

Then they went away.

Royalex is Dead

Royalex was developed in the 1970s by the Uniroyal Corporation. Since then it’s been used by dozens of canoe manufacturers to produce thousands of durable performance canoes. In 2000 the Royalex division was sold by Uniroyal to Spartech, which continued to produce Royalex sheets for canoe production. In 2013 Spartech sold to plastics company PolyOne, which took a hard look at Royalex sales numbers. The company determined that Royalex was unprofitable and took steps to shutter the operation. PolyOne closed down Royalex production in 2014. Canoe manufacturers ordered up their last sheets, built their final Royalex canoes and turned the page on a historic chapter in paddlesports history. Royalex was dead.

The remaining Royalex canoes made their way through the retail pipeline. Prices crept upward as demand for a finite number of canoes rose. The value of used Royalex canoes increased. By the time all the remaining stock was gone, the price of a Royalex canoe rose above $1700. Even at those prices they sold out. There simply wasn’t an alternative to fill the Royalex niche in the paddlesports world.

Doing Without

What happened next depends on which canoe company you’re talking about. With Royalex gone, some companies shifted their Royalex production into rotomolded canoes. For example, Old Town Canoe had previously produced the iconic Penobscot 16 and 17 canoes in Royalex. With Royalex gone, these models shifted over into polyethylene. Other companies worked to replace Royalex with composite constructions. Wenonah Canoe, where I work now, had long produced durable canoes from a polyester/fiberglass material called Tuf-Weave. Wenonah promoted Tuf-Weave as a Royalex alternative. Nova Craft Canoe developed an impact resistant composite construction that they called Tuff-Stuff to fill the Royalex niche. Both companies produced rotomolded plastic canoes as well. Many canoe companies were learning to do without Royalex.

But not all companies.

Several prominent canoe brands produced boats almost exclusively from Royalex. For these companies, the loss of Royalex was a crisis. Without Royalex they would go out of business entirely. Esquif Canoe was one of these brands.

Esquif owner and founder Jacques Chasse came up with a novel solution for the Royalex crisis–he would make his own. Chasse set out on a four-year quest to develop a Royalex replacement. The end result was T-Formex, a material that perfectly mimics the performance profile of Royalex.

T-Formex

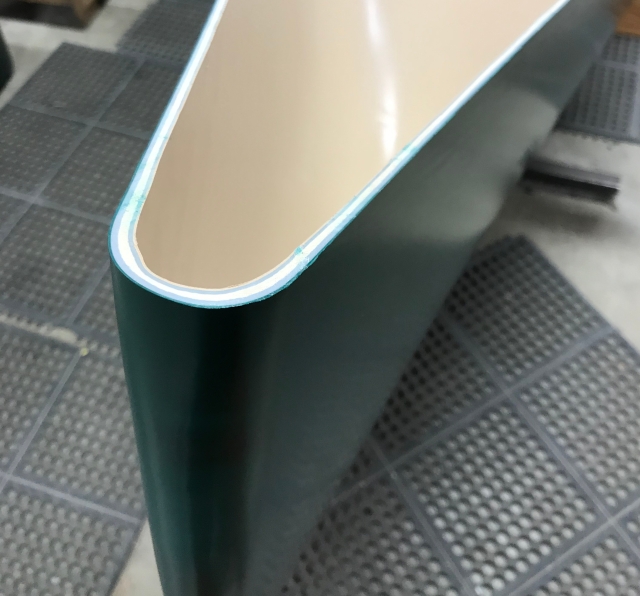

T-Formex is a sandwich of ABS (Acrylonitrile Butadine Styrene) plastic, expanding foam core and a proprietary outer skin. It shares Royalex’s extreme impact resistance and durability. The outer skin slides smoothly over rocks and doesn’t show scratches as much as composite canoes. Weight is very similar to Royalex. Stiffness and paddling performance is excellent.

T-Formex canoes cost more than Royalex canoes did. By their nature they must. Royalex was eliminated by PolyOne because it wasn’t profitable. For any replacement to be sustainable, it must pay its own way. So pricing has to reflect cost of materials and manufacturing. That said, T-Formex canoes are still quite affordable. They cost around $2000–at least $1000 less than a comparable composite canoe and about a third more than a heavier polyethylene canoe.

Like Royalex, T-Formex offers exceptional value. T-Formex canoes are modestly priced, light enough to cartop and tough as nails. No composite canoe material can match the impact resistance and worry free maintenance of T-Formex. Rotomolded plastic canoes are tough and affordable, but they’re much heavier.

T-Formex hits the sweet spot.

Market Reception

So, there you go, job done, right? Now that we have a true Royalex replacement things should go back to the way they used to be. T-Formex will come to dominate canoe construction the way that Royalex did back in the 1990s.

Maybe.

In 2017 Esquif and Wenonah launched T-Formex on the North American canoe market. That’s three years ago. Sales have been good, but they haven’t come close to the numbers that were being produced in the heyday of Royalex. So far, T-Formex hasn’t taken off as quickly as we had hoped.

Part of my job at Wenonah is to think about why this is.

T-Formex Myths

One reason may simply have to do with market penetration and volume of production. Back at the height of it’s popularity, Royalex was used by all the major canoe manufacturers in North America. There were some heavy hitters out there slinging Royalex hulls. Old Town was almost certainly the biggest, but the combined impact of Royalex canoes from Wenonah, Esquif, Dagger, Mad River, Nova Craft and others can’t be underestimated. Royalex was ubiquitous. The material was well known by the paddling public.

Today, T-Formex is only being used by a small group of manufacturers, the largest of which are Esquif and Wenonah. Compared to Royalex it isn’t as well understood or widely promoted. T-Formex is less visible.

Visibility is certainly a factor, but I think the marketing environment is nearly as important. When Royalex disappeared, all the manufacturers had to make do with different materials that weren’t as good for the job. Heavier plastic canoes that paddled like tanks. Less durable composite canoes that required more upkeep. Neither of these constructions were an adequate replacement for Royalex, but they were all the industry had to work with.

The forced change in materials came with a major change in marketing. Composites companies pushed composites. Rotomolders worked hard to convince the public that poly canoes were as good a value as Royalex. All the stories changed. All the sales pitches. The ads. The narratives. Those narratives are still out there, driving the conversation in the paddlesports world.

On top of this, most canoe manufacturers aren’t using T-Formex yet. Maybe that will change in the future, but for now, the majority of the canoe industry has a vested interest in downplaying the advantages of this new material and keeping the narrative focused on poly and composite. As long as this the case, those companies who are working with T-Formex will be going against the dominant stream of the paddlesports industry.

Obviously Wenonah and Esquif have a vested interest in promoting T-Formex. It works both ways. We all have our own unique perspectives and biases. People tend to do what they are paid to do.

I’m paid to sell Wenonah canoes, so I’m far from an impartial observer. On the other hand, I’m in a unique position to make a comparison between materials. Wenonah makes canoes from composites and rotomolded polyethylene as well as T-Formex. We make durable composite canoes from Tuf-Weave and aramid fabrics, and we build heavy, impact resistant canoes from poly. Since we manufacture canoes using all three processes we aren’t locked in to promoting one of them. This makes it easier to consider the advantages of T-Formex in an unbiased way.

The more I’ve learned about T-Formex and it’s current place in the paddlesports market the more I’ve realized that there are some persistent myths about T-Formex that need dispelling. A big part of why I wrote this post is to correct some of the misconceptions that people have about the material. Even people with years of experience in the industry.

Here are my top four.

Myth #1: T-Formex is too heavy

Too heavy compared to what? Rotomolded poly canoes are much heavier than T-Formex canoes. There’s a big difference between picking up a 70 pound canoe and a 90 pound canoe. Most people can get a 70 pound canoe onto the roof rack and carry it from the car to the water. Cartopping a heavier poly canoe is a real challenge. Compared to poly, T-Formex canoes are light.

Of course, T-Formex canoes are heavier than composite canoes, and if weight savings is the primary concern composites are a better choice. That said, composite constructions don’t have the same kind of durability that T-Formex canoes have. Even the toughest composites are more fragile and require more maintenance than a T-Formex canoe. On top of this they cost much more.

What about comparing T-Formex to Royalex? Weren’t Royalex canoes lighter? Yes. They were. At the height of Royalex construction it got to the point that practically every canoe design had a specific sheet of Royalex that was spec’ed just for that hull. This, combined with some fine tuning in the thickness of the ABS substrate and foam core allowed weights to come down a little bit, especially in recreational designs. It’s safe to say that Royalex canoes were a little lighter than T-Formex canoes are today.

How much lighter? Not much. Our records show that Wenonah’s T-Formex canoes come in at about 5 percent heavier than similar models built from Royalex. In most models the difference is a few pounds.

Myth #2: T-Formex is too expensive

I hear this one a fair bit from retailers and sales reps. A lot of us have been working in the paddlesports industry for a long time. We remember $1200 Royalex boats, and compared to that price, $2000 for a T-Formex canoe seems expensive.

Again, you have to ask, compared to what?

Comparing the price of a T-Formex canoe today to what Royalex cost back in the 90’s doesn’t make much sense. Today, $1200 will buy you a rotomolded poly canoe. Back then, that same plastic canoe would have cost $700. Like just about everything in this world, the price of canoes has gone up. But the relative cost of T-Formex and polyethylene canoes has remained fairly constant.

Like Royalex canoes before them, T-Formex canoes represent the best value in the canoe market. They’re much tougher than composite canoes, much lighter than poly canoes and priced in between the two. Right in the sweet spot.

Photo: Mike Robinson.

Myth #3: Other materials are just as good, or better than T-Formex

This one is just plain wrong. There are a lot of good materials out there for canoebuilding, but none of them matches the performance characteristics of T-Formex.

Burly composite constructions will do in a pinch to run down a rocky river, but they’ll get pretty beat up in the process. None of them can be wrapped around a boulder in whitewater, Z-dragged to the bank and pounded back into serviceable shape. None of them are a good choice for a family canoe the might get left Up North at the cabin for the kids to use. All of them are more expensive than T-Formex.

Poly canoes are heavy, don’t paddle as well as T-Formex canoes and don’t hold their shape as well over time. They’re a decent option if price is the single most important factor, but they’re not in the same class as T-Formex canoes.

Like Royalex, T-Formex has a unique set of qualities that set it apart in the marketplace.

Proof of this comes from discussions I’ve had with outfitters and summer camps across northern Minnesota. Liveries up on the Gunflint Trail that outfit trips on the Granite River in the Boundary Waters have been nursing along their aging Royalex fleets because nothing else held up to the abuse the same way. Camps that run wilderness trips have experimented with different materials but found that the poly canoes were too heavy for campers and the composite canoes couldn’t take a beating like Royalex. T-Formex is the only real solution for situations like these. Nothing else comes close.

Myth #4: There isn’t enough demand for T-Formex

This one I hear once in a while from retailers. T-Formex is a relatively new material and some shops are unsure about stocking it. Wenonah dealers have done very well with our composite canoes over the past few years and trying something new always comes with a risk. Is there really a demand for T-Formex out there?

I believe there is.

We’re coming to the end of one of the most extraordinary years in the history of paddlesports. It’s hard to overstate the impact that COVID-19 has had on the canoe and kayak industry. Factories were shuttered during lockdowns. Demand for canoes and kayaks exploded as people spent more time outdoors. Warehouses went empty. Shops sold through their inventory. Orders went through the roof.

Demand for canoes is at all-time high levels and there is no way to meet that demand with composite canoes.

Right now at Wenonah we have orders for composite canoes on the books that will fill our production capacity well into spring. All the other major composite canoe manufacturers are in the same boat. Some builders are so backed up that a canoe ordered today won’t be delivered until July of next year.

The shortage of composite canoes means that more people will find themselves faced with the choice of a heavy poly canoe or no canoe at all. T-Formex is a much better option.

In the current marketplace there is definitely a demand for quality canoes at an affordable price. That means there’s plenty of demand for T-Formex.

The Future of T-Formex

Where will T-Formex go from here? I see a couple potential paths.

First, T-Formex could carve out a small niche in the canoe market for whitewater and expedition trippers who need a seriously tough canoe. A specialty niche within a specialty market. Small numbers of technical canoes for true paddling enthusiasts. Never breaking out into the mainstream.

More likely, I think, is that T-Formex will being to make inroads into the recreational canoe market much in the same way that Royalex did back in the 1990’s and 2000’s. One of the reasons that Royalex canoes were so popular with dealers and paddlers back then is that you could get them. Yes, they were quality canoes that outperformed other materials, but they were also available in greater quantities than composite canoes were.

Like Royalex canoes before them, T-Formex canoes are faster to build than composites and can be produced in greater volume. Hulls are quicker to mold. Assembly is more standardized. The whole process is streamlined in a way that composite construction is not. This means that T-Formex production can be ramped up to meet demand in a way that composites construction can’t.

In the end this may mean that T-Formex will break into the mainstream canoe market because it is the only material that is capable of meeting current demand for quality canoes. The material has a unique performance profile, but its also uniquely suited to rapid production. There’s no other material that can be used to build as many quality canoes and offer them at an affordable price. Once again, T-Formex is in a class of its own.

There are a whole lot of paddlers out there right now looking for canoes. T-Formex canoes are affordable, tough, worry free and…available.

2 comments

Nice informative article. Excellent discussion of canoe materials.

Good job Brian. I remember you from the life tools days. Best explanation of royalex v Tformex I have seen. Bob Herubin